基于PWM两相步进马达驱动IC的设计

基于PWM两相步进马达驱动IC的设计摘要随着马达在消费类电子市场产品中的广泛应用,马达驱动芯片受到越来越多的关注,而步进马达驱动作为马达驱动中重要的分支,不可避免地受到了许多科研机构和公司重视。本文在详细论述了步进马达驱动原理的基础上设计了一种高压、大电流、中等功率、基于PWM的两相混合式步进马达驱动IC,主要应用于打印机、复印机、电脑扫描和绘图仪等位置与速度伺服系统控制。芯片可控额定最高电压V(max)为36V,最大输出连续电流Io(max)为1.2A,功率MOS输出晶体管的导通电阻RDS(on)为1.8Ω。本文设计的芯片主要是基于PWM的两相混合式步进马达驱动IC,它利用PWM输入信号控制...

相关推荐

-

上海市民办上宝中学2020-2021学年八年级下学期3月月考英语试题(原卷版)

2024-10-14 25

2024-10-14 25 -

上海市民办新复兴初级中学2020-2021学年九年级上学期期中英语试题(解析版)

2024-10-14 25

2024-10-14 25 -

上海市民办新复兴初级中学2020-2021学年九年级上学期期中英语试题(原卷版)

2024-10-14 29

2024-10-14 29 -

上海市民办新复兴初级中学2021-2022学年八年级下学期期中英语试题

2024-10-14 30

2024-10-14 30 -

上海市民办新竹园中学2020-2021学年八年级上学期期中英语试题(解析版)

2024-10-14 32

2024-10-14 32 -

上海市民办新竹园中学2020-2021学年八年级上学期期中英语试题(原卷版)

2024-10-14 25

2024-10-14 25 -

上海市闵行区2017届九年级4月质量调研(二模)英语试题及答案(word解析版)

2024-10-14 25

2024-10-14 25 -

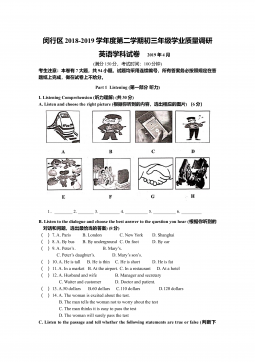

上海市闵行区2018-2019学年八年级下学期期末质量调研英语试卷(解析版)

2024-10-14 30

2024-10-14 30 -

上海市闵行区2018-2019学年八年级下学期期末质量调研英语试卷(原卷版)

2024-10-14 30

2024-10-14 30 -

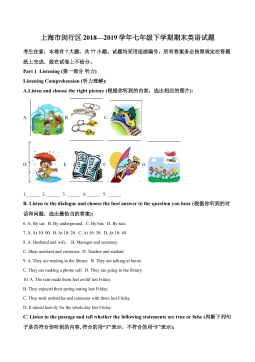

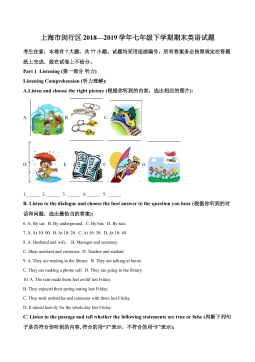

上海市闵行区2018—2019学年七年级下学期期末英语试题(解析版)

2024-10-14 33

2024-10-14 33

相关内容

-

上海市民办新竹园中学2020-2021学年八年级上学期期中英语试题(原卷版)

分类:初中教育

时间:2024-10-14

标签:无

格式:DOC

价格:12 积分

-

上海市闵行区2017届九年级4月质量调研(二模)英语试题及答案(word解析版)

分类:初中教育

时间:2024-10-14

标签:无

格式:DOCX

价格:12 积分

-

上海市闵行区2018-2019学年八年级下学期期末质量调研英语试卷(解析版)

分类:初中教育

时间:2024-10-14

标签:无

格式:DOCX

价格:12 积分

-

上海市闵行区2018-2019学年八年级下学期期末质量调研英语试卷(原卷版)

分类:初中教育

时间:2024-10-14

标签:无

格式:DOCX

价格:12 积分

-

上海市闵行区2018—2019学年七年级下学期期末英语试题(解析版)

分类:初中教育

时间:2024-10-14

标签:无

格式:DOC

价格:12 积分